Insulated Pipeline

Keywords:

Offshore Pipeline

Category:

Introduction

Insulated pipes are a special type of pipe system that wraps insulation materials (such as polyurethane foam, rock wool, glass wool, etc.) around the outside of the pipes to reduce the heat exchange between the medium inside the pipes and the outside, thereby achieving the purposes of insulation, cold preservation or energy conservation. Its core function is:

◆ Maintain stable medium temperature: Prevent high-temperature media (such as hot water, steam) from dissipating heat or low-temperature media (such as chilled water, liquefied gas) from absorbing heat.

◆ Reduce energy consumption: Minimize heat/cold loss and save energy.

◆ Protect pipeline safety: Prevent problems such as condensation, corrosion, and freezing cracking caused by excessively high or low temperatures in pipelines.

Application scenarios

Building HVAC: hot water heating pipes, central air conditioning chilled water pipes, domestic hot water pipes.

Industrial manufacturing: Chemical steam pipelines, high-temperature material conveying pipelines for food processing, cold insulation pipelines for refrigeration systems.

Energy sector: Steam pipelines for thermal power stations, centralized heating networks, and insulated pipelines for oil and gas transportation.

Refrigeration engineering: Cold storage refrigerant pipelines, liquid ammonia/liquid nitrogen transportation pipelines (requiring cold insulation to prevent vaporization).

Municipal engineering: Urban centralized heating pipe networks, hot spring water transportation pipelines, and insulation systems for underground utility tunnels.

The technical advantages of insulated pipes

High efficiency and energy conservation

The heat loss is reduced by more than 80% compared with non-insulated pipes. For example, after insulation of steam pipes, the heat loss per kilometer can be reduced from 200kJ/m · h without insulation to below 40kJ/m · h.

Convenient construction

Prefabricated insulated pipes (such as polyurethane insulated pipes with a "pipe-in-pipe" structure) can be processed in advance in the factory and assembled on site, shortening the construction period.

Long service life

The combination of high-quality insulation materials and protective layers can extend the service life of pipelines to 20 to 30 years (for instance, the high-density polyethylene outer protective pipe has strong corrosion resistance).

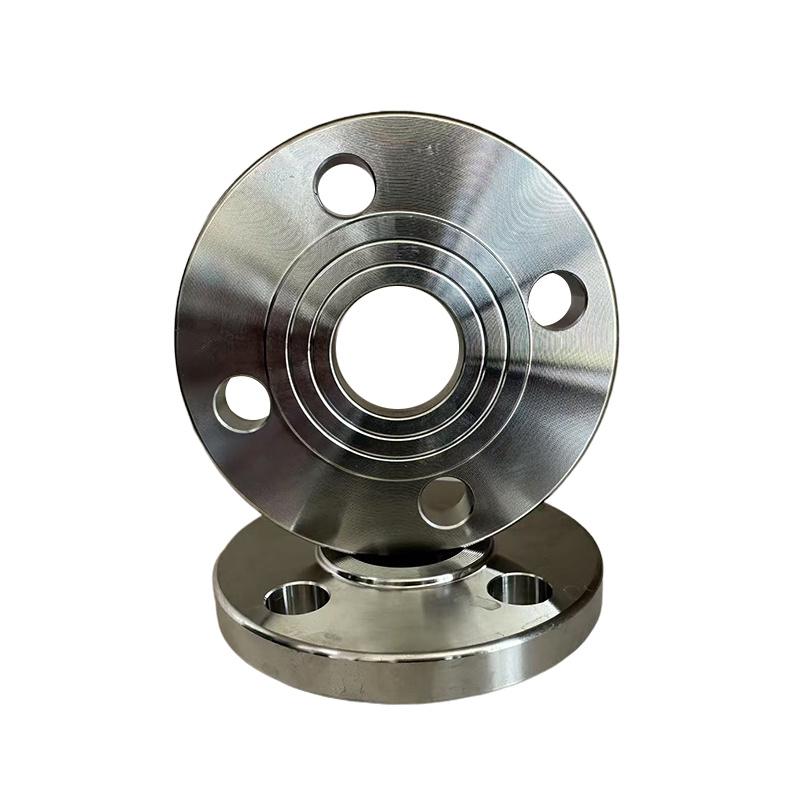

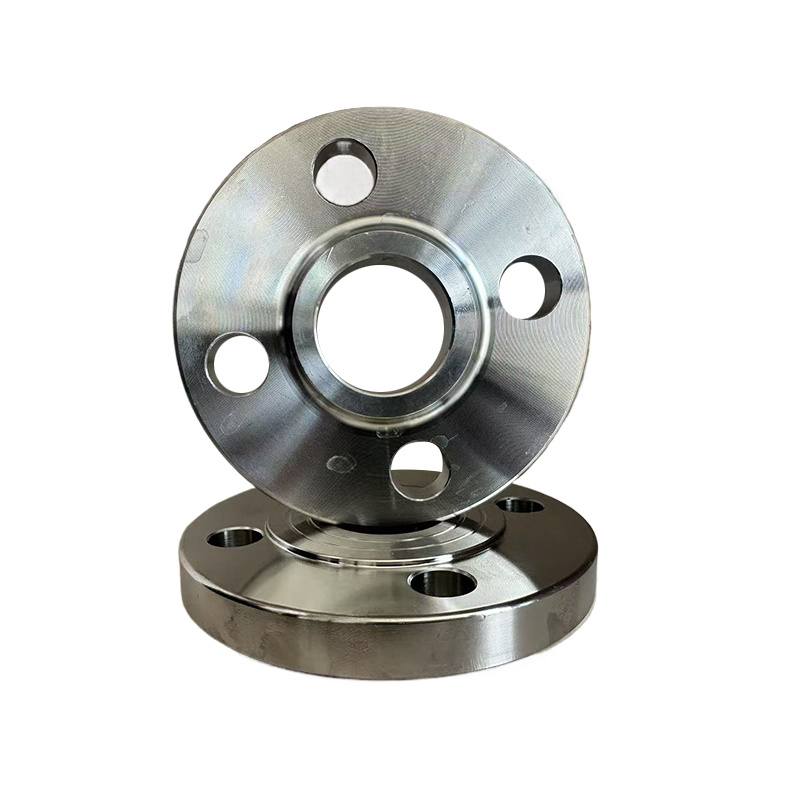

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products