High-pressure plastic-coated bend

Keywords:

Offshore Pipeline

Category:

Introduction

High-pressure plastic-coated elbow pipes are pipe fittings used in high-pressure pipeline systems. By coating the inner or outer walls of metal elbow pipes (such as carbon steel, stainless steel, etc.) with high-molecular plastic coatings, they possess both the strength of metals and the corrosion resistance, wear resistance, and anti-scaling properties of plastics. The following is a detailed description of its core features and application scenarios:

Base material selection

The metal matrix is usually carbon steel (such as Q235, 20# steel), alloy steel (such as 12Cr1MoV) or stainless steel (such as 304, 316L), ensuring structural strength under high-pressure conditions.

Coating materials mainly include:

Polyethylene (PE) : Corrosion-resistant and water-resistant, suitable for the transportation of liquids at normal temperature.

Epoxy resin (EP) : Resistant to acids and alkalis, with strong adhesion, suitable for highly corrosive scenarios such as chemical engineering and petroleum.

Cross-linked polyethylene (XLPE) : It can withstand high temperatures (up to over 90℃) and has superior mechanical properties.

Polytetrafluoroethylene (PTFE) : resistant to strong corrosion and high temperatures (below 260℃), but it is relatively expensive.

Coating process

Hot-dip plastic coating: Preheat the metal elbow pipe and then immerse it in molten plastic powder to form a uniform coating. It is suitable for thick coatings (0.3 to 1.0mm).

Electrostatic spraying: Plastic powder is adhered to the pipe wall through electrostatic adsorption and then cured at high temperature. The coating is thinner (0.1 to 0.3mm) but the surface is smoother.

Rotational molding process: Plastic powder is injected into the mold, heated and rotated to ensure uniform coating adhesion. It is suitable for large-diameter pipe fittings.

Main application fields

The oil and gas industry

High-pressure oil/gas pipeline elbows prevent corrosion by media such as hydrogen sulfide (H₂S) and carbon dioxide (CO₂).

Chemical Engineering and Pharmaceuticals

Pipeline systems for transporting strong acids (such as sulfuric acid), strong alkalis (such as sodium hydroxide), or organic solvents.

Water supply and drainage engineering

High-pressure pipe elbows for drinking water transportation (sanitary grade PE/EP coating), industrial circulating water, and sewage treatment.

Marine engineering

Offshore platform pipelines and seawater cooling systems, resistant to salt spray and seawater corrosion.

Heating and HVAC

High-temperature hot water or steam pipes (high-temperature resistant coatings such as XLPE and PTFE should be selected).

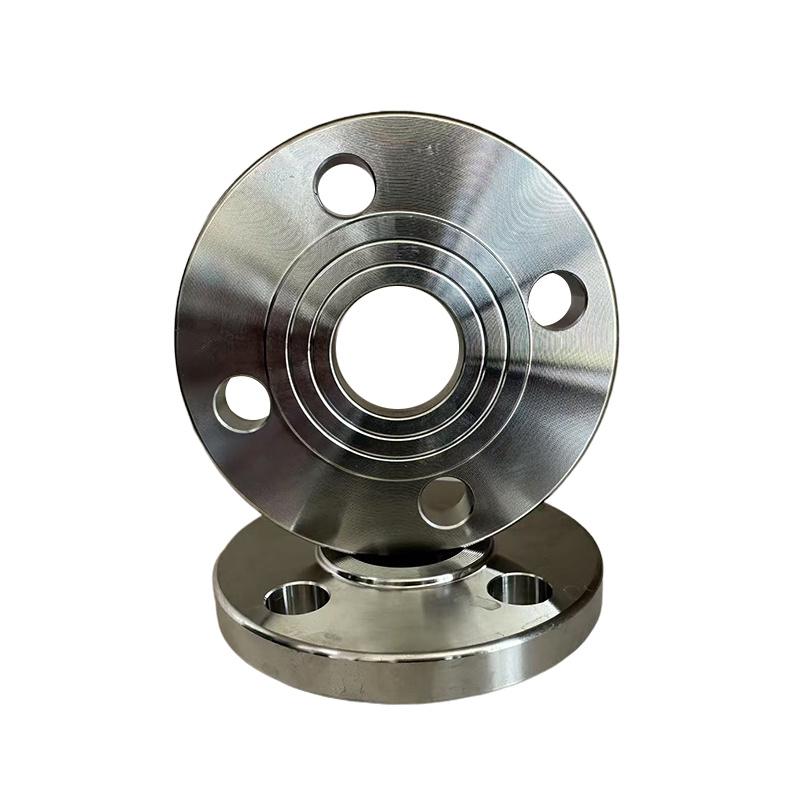

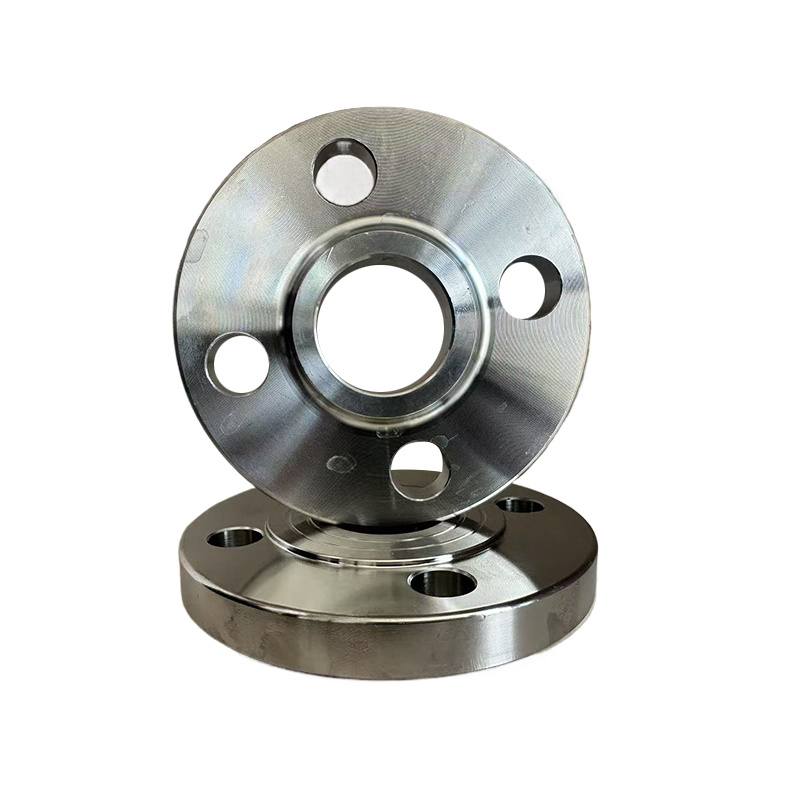

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products