High-pressure pipe cap

Keywords:

Offshore Pipeline

Category:

Introduction

Definition and Application

High-pressure pipe caps are pipe fittings used to seal the ends of high-pressure pipelines. They are fixed to the pipelines through welding or threaded connection and other methods, serving to seal, isolate or temporarily block the pipelines. Its main application scenarios include:

End closure of pipeline system: Such as temporarily closing the end after the pipeline construction is completed, or permanently terminating the pipeline fluid transportation.

Equipment connection assistance: Used in conjunction with valves, instruments and other equipment, it facilitates the maintenance, inspection or pressure testing of pipeline systems.

Special working condition protection: In harsh environments such as high pressure, high temperature, and corrosive media, prevent the leakage of the medium in the pipeline to ensure system safety.

Main features

High-strength pressure resistance

Made of high-quality steel (such as carbon steel, stainless steel, alloy steel, etc.), its strength is enhanced through forging, heat treatment and other processes, and it can withstand pressures up to tens of megapascals (MPa).

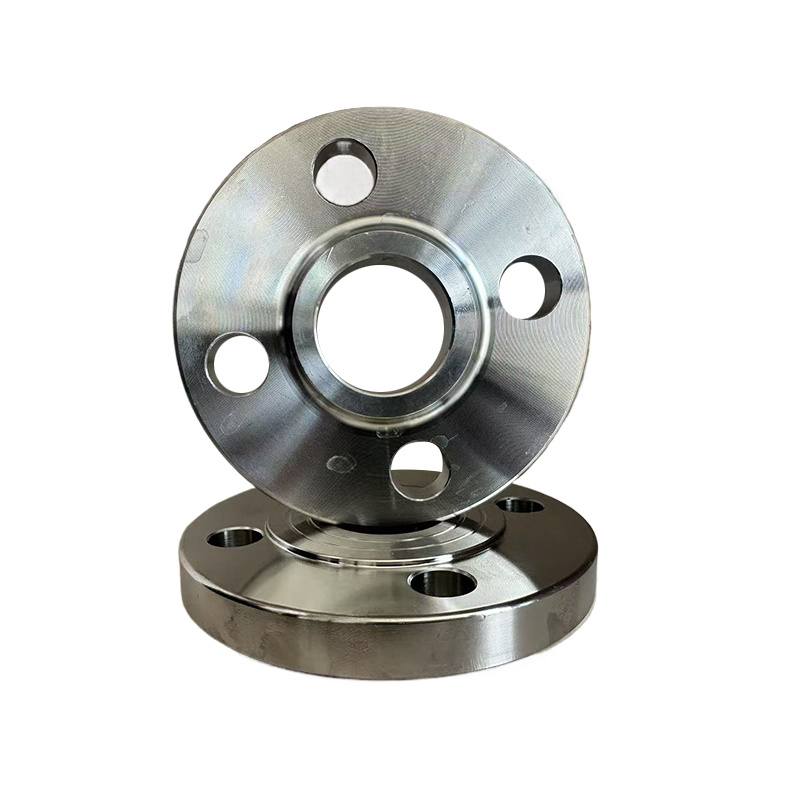

Excellent sealing performance

The end face is usually processed into a plane, a convex surface or a concave surface, and is used in conjunction with a sealing gasket to ensure no leakage under high-pressure conditions.

Corrosion resistance and high-temperature resistance

Select corrosion-resistant materials (such as 316L stainless steel, duplex steel, etc.) based on the characteristics of the medium, which are suitable for transporting corrosive fluids such as acids, alkalis, oil and gas. Heat-resistant alloy materials (such as 12Cr1MoV, P91, etc.) can be selected for high-temperature working conditions.

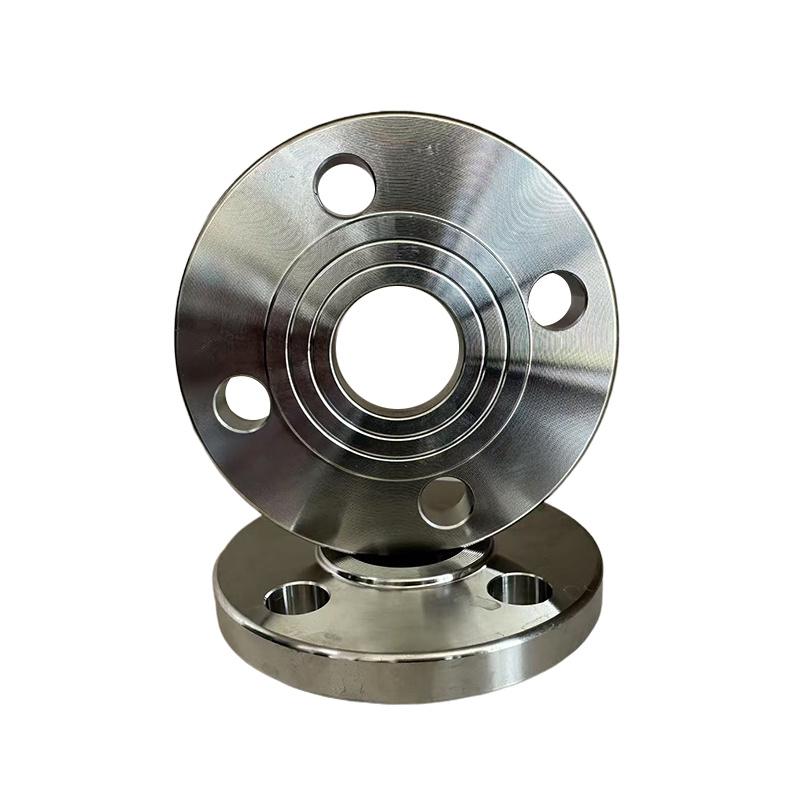

The structural forms are diverse.

Circular pipe caps: The most common, they are divided into hemispherical, elliptical, disc-shaped, etc. They are evenly stressed and have good compressive resistance.

Conical pipe caps: Used for end sealing of reduced-diameter pipes or in scenarios where gradual pressure reduction is required.

Square/irregular-shaped pipe caps: Specially customized structure, suitable for non-circular pipes or special installation requirements.

Application field

Petrochemical industry: High-pressure oil and gas pipelines, inlet and outlet sealing of reaction vessels, etc.

Power industry: End sealing of steam pipelines and high-pressure feedwater pipelines in thermal power plants.

Natural gas transmission: The cut-off points of long-distance pipelines and the connection parts of equipment in compression stations.

Shipbuilding industry: Sealing and protection of high-pressure seawater pipelines and fuel pipelines.

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products