Alloy pipe cap

Keywords:

Offshore Pipeline

Category:

Introduction

Definitions and core features

Alloy pipe caps are pipe sealing components made of alloy materials (such as chromium-molybdenum steel, stainless steel, nickel-based alloys, etc.), fixed at the end of the pipe through welding or threaded connection, and are used for sealing and protection under harsh working conditions such as high pressure, high temperature, and corrosion. Its core advantage stems from the special performance combination of alloy materials:

◆ High strength and high toughness: Superior to ordinary carbon steel, with stronger impact resistance and fatigue resistance.

◆ High-temperature resistance and corrosion resistance: Suitable for scenarios such as transporting steam, oil and gas, acid and alkali media, etc.

◆ Excellent weldability and processability: It can be made into different structural forms through forging, cutting and other processes.

Key technical parameters

Nominal diameter (DN) : Suitable for the inner diameter of pipes, ranging from DN15 to DN1200+ (customizable for extra-large specifications).

Nominal pressure (PN) : From PN16 (1.6MPa) to PN160 (16MPa). Customized for ultra-high pressure conditions (such as PN250).

Wall thickness grades: Sch40, Sch80, Sch160, etc., corresponding to the strength requirements under different pressure grades.

Execution standards: The material standards (such as ASTM A182, GB/T 1220) and manufacturing standards need to be clearly marked.

Application field

Petrochemical industry

The inlet and outlet of the high-pressure hydrogenation reactor are sealed, and the end of the acidic gas pipeline is sealed (which needs to resist H₂S corrosion).

Power industry

The end of the main steam pipeline of the supercritical unit (temperature ≥540℃, pressure ≥25MPa) and the high-temperature reheating pipeline.

Marine engineering

Submarine oil pipelines (seawater corrosion + high-pressure environment), high-pressure fire protection pipelines on platforms.

The field of new energy

High-pressure storage and transportation pipelines for hydrogen energy (which need to resist hydrogen embrittlement, such as Inconel 718 selected), and sealing components of fuel cell systems.

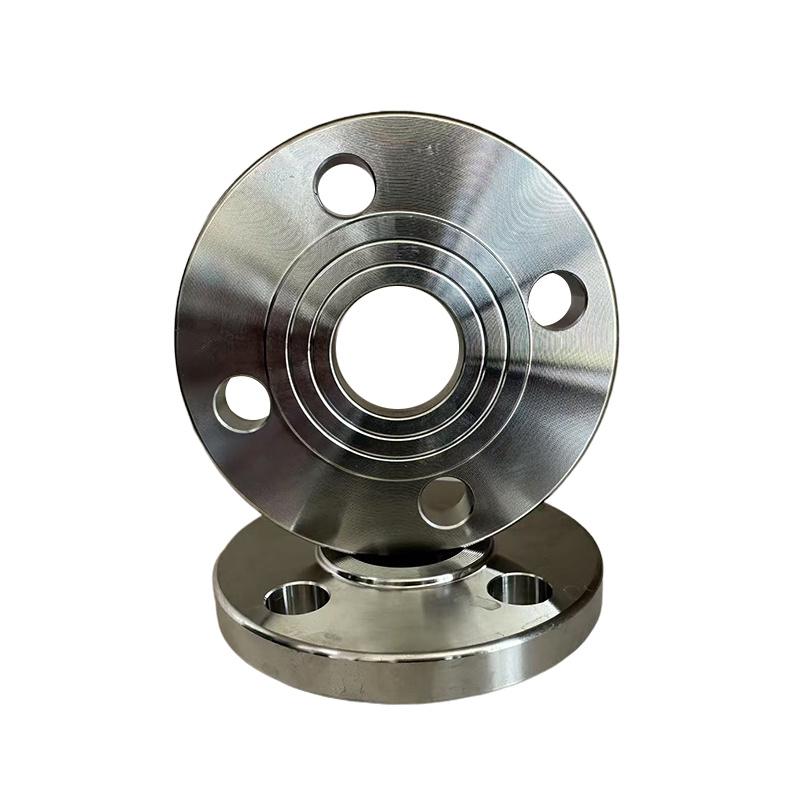

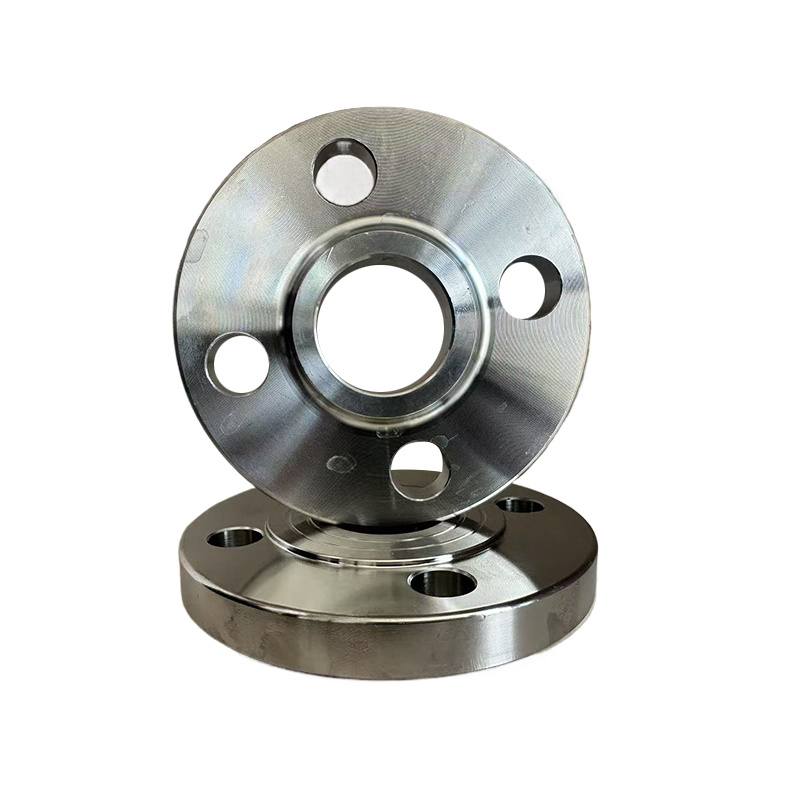

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products