Plastic-Coated Pipe

Keywords:

Offshore Pipeline

Category:

Introduction

Core definitions and structure

Plastic-coated pipes are made by evenly covering plastic materials (such as PE, EP, PP, FEP) on the inner and outer surfaces of metal pipes (such as carbon steel, stainless steel, etc.) through special processes (such as electrostatic spraying, hot-dip plastic coating, rotational molding, etc.), forming a continuous and dense protective film. This film combines the high strength of metal pipes with the corrosion resistance and wear resistance of plastics.

Typical structure

Base pipe: Carbon steel seamless pipe, welded pipe or stainless steel pipe (providing mechanical support).

Coating: The thickness is usually 0.3-2mm, and the material is selected according to the working conditions:

PE (polyethylene) : Corrosion-resistant and highly flexible, it is suitable for the transportation of drinking water and seawater.

EP (Epoxy Resin) : It is heat-resistant and has strong adhesion, making it suitable for the transportation of chemical acid and alkali solutions.

FEP (Fluoroplastic) : Resistant to strong corrosion and high and low temperatures (-200℃ to 200℃), it is used in extreme environments (such as the semiconductor industry).

Main application scenarios

Building water supply and drainage

Domestic drinking water transportation and fire sprinkler system (replacing galvanized pipes to avoid secondary water pollution).

Industrial anti-corrosion

Acid/alkali solution transportation in chemical enterprises, desulfurization wastewater treatment in the power industry, and tailings slurry transportation in mines.

Oil and gas field

Oilfield water injection pipelines (resistant to CO₂ and H₂S corrosion), natural gas gathering and transportation pipelines (resistant to sulfide stress cracking).

Marine Engineering

Seawater desalination plants and seawater transportation pipelines for offshore drilling platforms (resistant to chloride ion corrosion).

Food and Medicine

Beverage production lines, purified water pipelines for pharmaceutical factories (in compliance with GMP certification requirements).

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

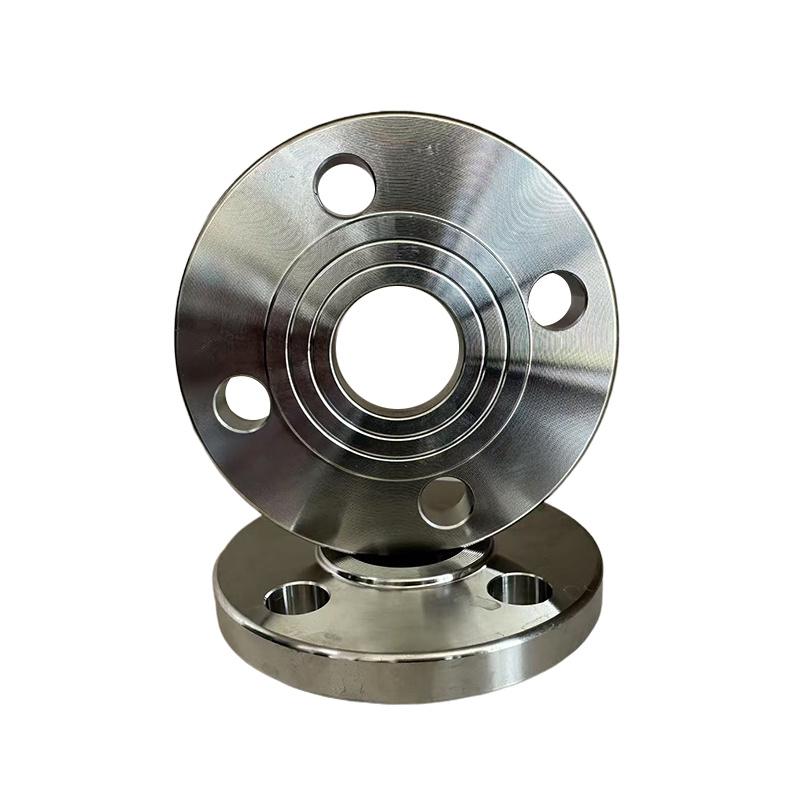

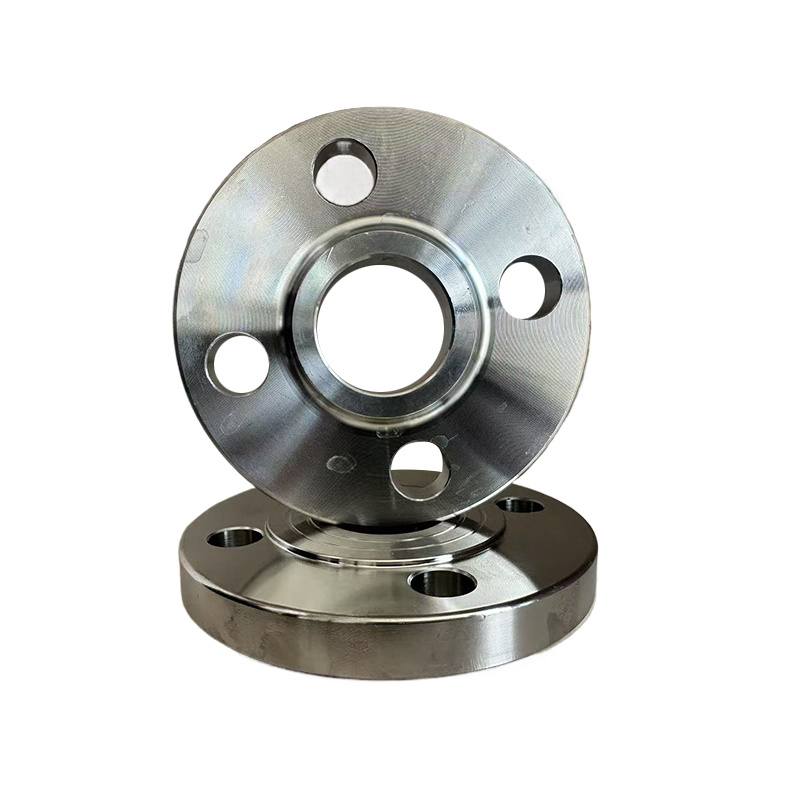

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products