Tee

Keywords:

Offshore Pipeline

Category:

Introduction

A pipe tee is a pipe fitting used to connect a main pipe with one or two branch pipes to achieve fluid diversion or convergence. It is named for its shape resembling a "T" or "Y". The core functions include:

Diversion: Distributing the fluid in the main pipe to one or two branch pipes (for example, tap water is divided into multiple branch pipes from the main pipe).

Convergence: Collecting the fluids from two branch pipes into the main pipe (such as the convergence of sewage from different channels in industrial wastewater treatment).

Changing flow direction: In special layouts, the fluid direction is adjusted through a three-way valve (such as a branch of an air conditioning duct).

Main technical parameters

Nominal diameter (DN) : The diameters of the main pipe and the branch pipe (for example, DN200×150 indicates that the main pipe is DN200 and the branch pipe is DN150).

Wall thickness: Selected based on the pressure rating, the wall thickness of high-pressure tees can reach over 20mm (for example, the wall thickness of DN100 and PN100 tees is 14mm).

Execution standard

National standards: GB/T 12459 (Steel butt-weld Pipe fittings), GB/T 13401 (Steel Plate Butt-weld Pipe fittings).

American standards: ASME B16.9, MSS SP-83 (Threaded tee).

European standard: EN 10253-2 (butt-weld pipe fittings).

Manufacturing process

Forging: High-pressure tees are adopted, and the material density is increased through forging (such as alloy tees used in power stations).

Hot pressing forming: Commonly used for medium and low pressure tees, the tube blank is heated and then pressed into shape (such as carbon steel reducer tees).

Welding and splicing: Large-diameter tees (DN≥800) are separately pressed and then assembled and welded (such as municipal water supply pipelines).

Pipe tee are the core components for achieving flow diversion and convergence in pipeline systems. When selecting the type, the characteristics of the medium, pressure level, installation space and flow requirements should be comprehensively considered. Under harsh working conditions such as high pressure and corrosion, forged alloy or stainless steel butt-weld tees should be given priority, and the welding and inspection standards should be strictly followed. In civilian or low-pressure scenarios, plastic or threaded connection tees can be adopted to reduce costs and simplify installation. The correct use of tees can effectively ensure the fluid stability and safety of the pipeline system.

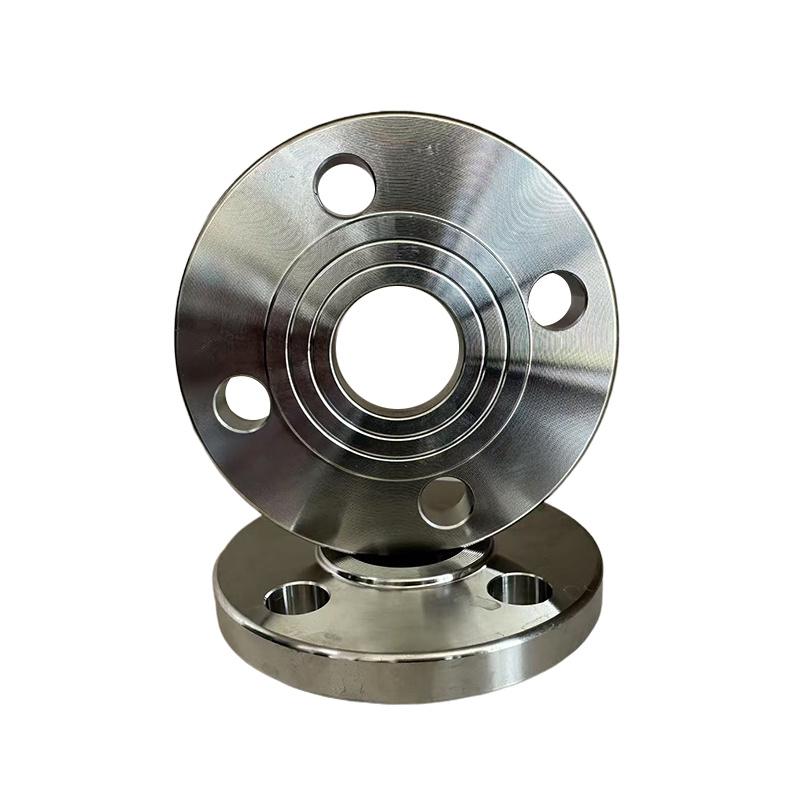

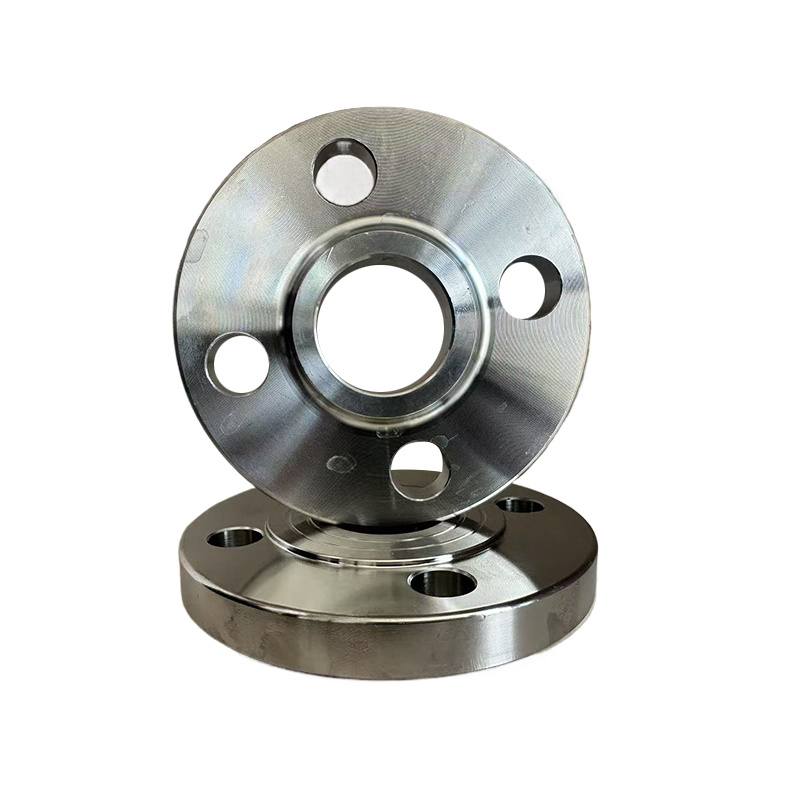

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products