Stainless Steel Seamless Pipe/Tube

Keywords:

Offshore Pipeline

Category:

Introduction

Core definitions and manufacturing processes

Stainless steel seamless pipe is a kind of hollow circular or special-shaped cross-section pipe without welding seams, which is made from stainless steel billets (such as round steel) through processes such as piercing, hot rolling, and cold rolling (drawing). Its characteristics are:

◆ Uniform structure: The pipe wall has no welds, offering superior mechanical properties and strong pressure-bearing capacity (up to over 100MPa).

◆ Corrosion resistance: Based on stainless steel materials (such as 304, 316L), it can resist acid, alkali, salt and atmospheric corrosion.

◆ High surface accuracy: The cold rolling (drawing) process can achieve an inner wall roughness of Ra≤0.8μm, making it suitable for precision fluid systems.

Main manufacturing process

Hot-rolled seamless pipe

Process: Round steel heating → piercing (forming rough tubes) → hot rolling and stretching → sizing → cooling → finishing.

Features: High production efficiency, suitable for large-diameter pipes (outer diameter 32-630mm), with relatively low surface accuracy.

Cold-rolled (drawn) seamless tubes

Process: Hot-rolled tubes → pickling → Cold rolling (multi-roll mill) or cold drawing (die drawing) → annealing → finishing.

Features: High dimensional accuracy (outer diameter tolerance ±0.3%), uniform wall thickness, suitable for small-diameter precision tubes (outer diameter 6-219mm).

Key features and advantages

Tensile strength: 520-795MPa (for 304 material), which is more than twice that of ordinary carbon steel pipes.

Fatigue resistance: The service life under cyclic loading can reach more than 10⁶ times (superior to welded pipes).

Corrosion resistance:

It is stable in media with pH ranging from 1 to 14. For instance, the 316L material has significantly better resistance to pitting corrosion in solutions containing chloride ions (Cl⁻) than 304.

Hygiene performance:

It has a high surface finish, is easy to clean, complies with the GB 14934 food-grade standard, and is widely used in the pharmaceutical and beverage industries.

High-temperature resistance performance:

The maximum working temperature of 304 material is 800℃, and that of 310S (06Cr25Ni20) can reach 1200℃. It is suitable for boilers and heat treatment equipment.

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

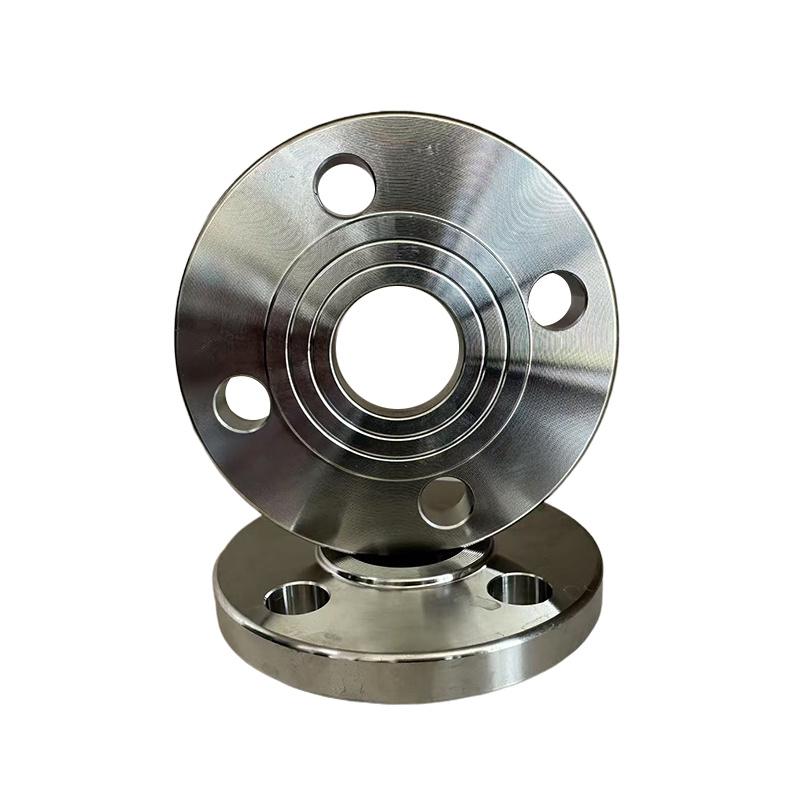

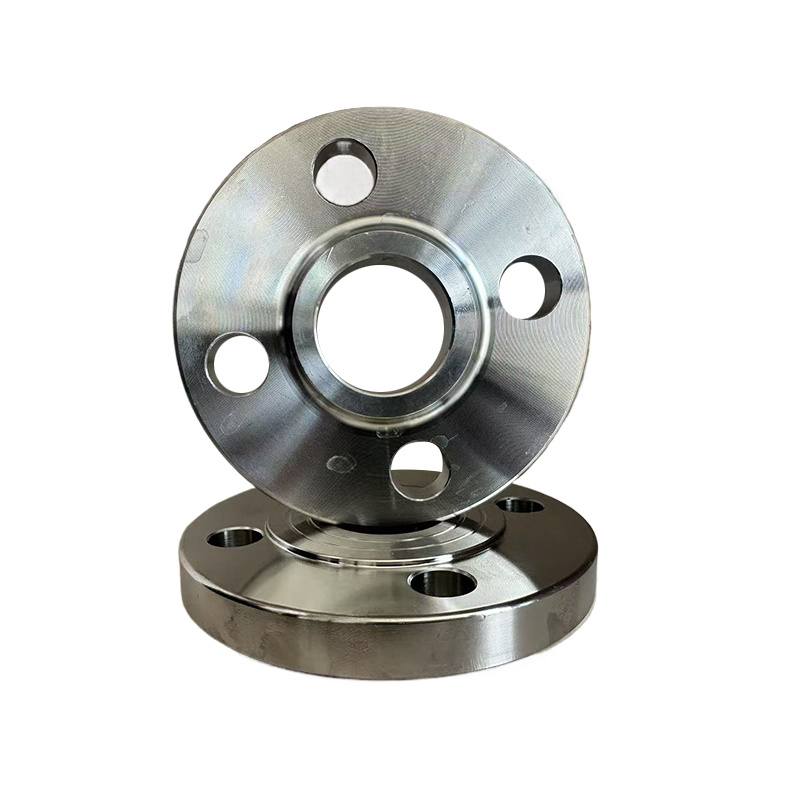

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products