Pipe cap

Keywords:

Offshore Pipeline

Category:

Introduction

A pipe cap is a closed component installed at the end of a pipe, which is connected to the pipe through welding, threading or flanging, etc. Its main functions include:

Sealed pipelines: Prevent the leakage of the medium inside the pipelines and ensure the safety of the system (such as temporary blocking or permanent sealing during construction).

Auxiliary maintenance: Facilitates pressure testing, cleaning or repair of the pipeline system (such as sectional inspection after temporary closure).

Structural support: In special designs, it can withstand the internal pressure of the pipeline and disperse the stress at the end.

Main technical parameters

Nominal diameter (DN) : Suitable for the inner diameter of pipes, ranging from DN15 to DN2000+ (extra-large diameters require customization).

Wall thickness: Selected based on the pressure level, the wall thickness of high-pressure pipe caps can reach over 20mm (for example, the wall thickness of DN100 and PN100 pipe caps is 14mm).

Execution standard

National standards: GB/T 12459 (Steel butt-weld Pipe fittings), GB/T 13401 (Steel Plate Butt-weld Pipe fittings).

American standards: ASME B16.9, ASME B16.11 (Socket welding and threaded pipe fittings).

European standard: EN 10253-2 (butt-weld pipe fittings).

Manufacturing process

Forging: It is used for high-pressure pipe caps, enhancing the density and strength of the material through forging (such as hemispherical pipe caps).

Stamping: Commonly used for medium and low pressure pipe caps, it features low cost and high efficiency (such as elliptical pipe caps).

Welding and splicing: For large-diameter pipe caps, they are assembled and welded after being pressed into sections (such as DN1200 and above).

As the end sealing component of the pipeline system, the selection of pipe caps needs to comprehensively consider the medium, pressure, temperature and installation requirements. The correct selection and installation of pipe caps can effectively ensure the sealing and safety of the pipeline system. Especially under harsh working conditions such as high pressure and corrosion, high-performance materials (such as alloys and stainless steel) and reliable connection methods (such as butt welding) should be given priority to ensure the long-term stable operation of the system.

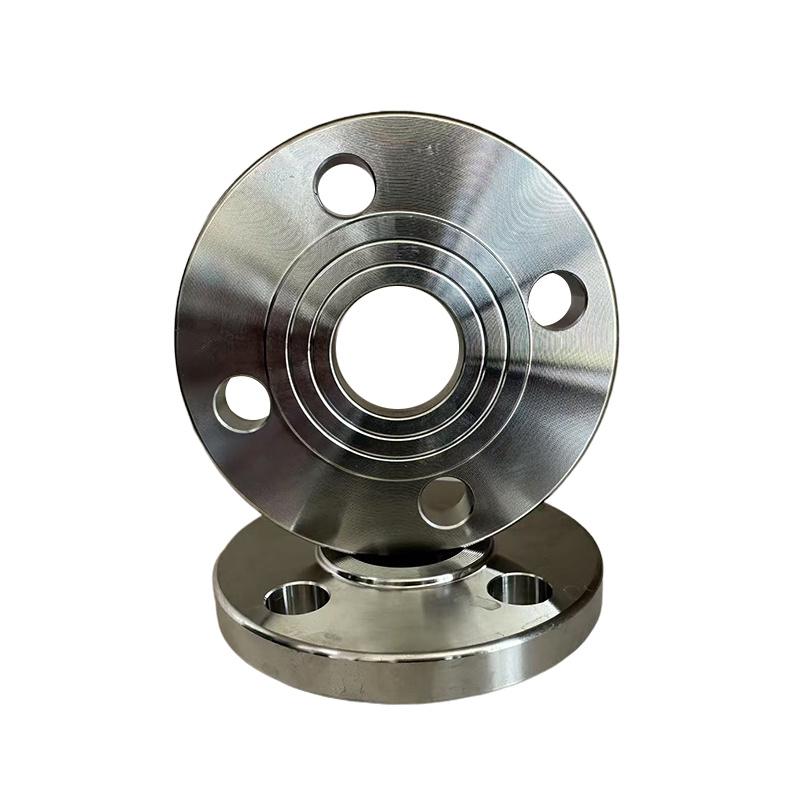

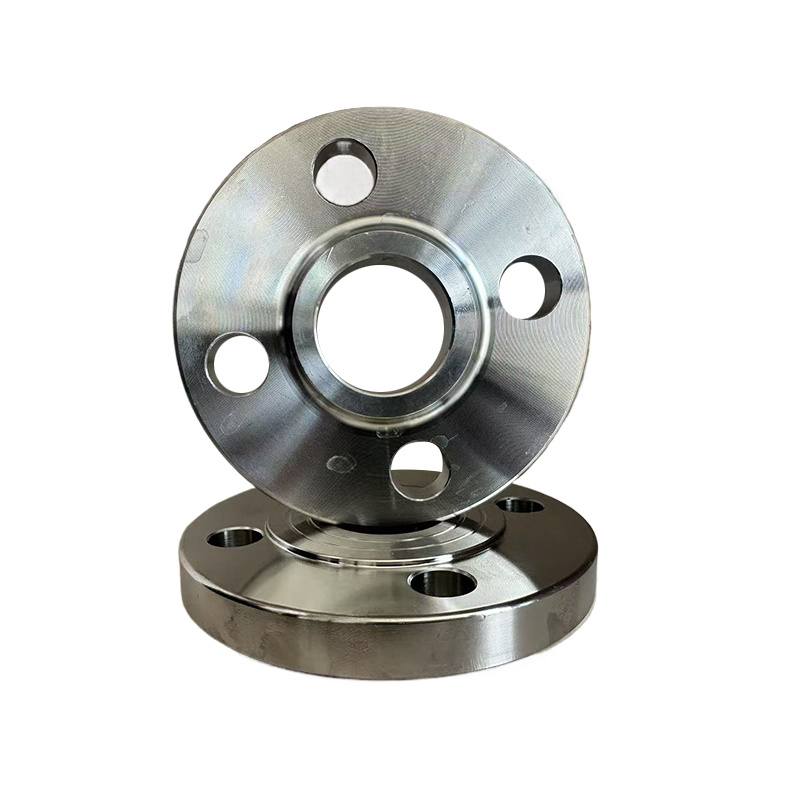

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products