High-Pressure Stainless Steel Seamless Pipe/Tube

Keywords:

Offshore Pipeline

Category:

Introduction

Core definitions and performance metrics

High-pressure stainless steel seamless pipe is a special type of pipe material that can withstand high pressure (usually ≥10MPa), made from high-quality stainless steel billets through piercing and hot/cold rolling. Its key performance indicators include:

Pressure resistance grade: The design pressure range is usually 10-100MPa (for example, the main circuit pipeline of a nuclear power plant needs to withstand 15.5MPa).

Material characteristics

Common grades: 304H (with high carbon content and good high-temperature strength), 316H, 321H (resistant to intergranular corrosion), 347H (containing Nb stabilizing element).

Yield strength: ≥205MPa (at room temperature), with a high strength retention rate at high temperatures (for example, yield strength ≥180MPa at 500℃ after 316H).

Dimensional accuracy: Wall thickness tolerance ≤±5% (for example, DN100×10mm pipe, wall thickness range 9.5-10.5mm), ensuring uniform pressure distribution.

Key technical characteristics

High-temperature and high-pressure resistance performance:

The 321H material does not sensitize after long-term use at 550℃ and has excellent creep resistance (the breaking strength at 10⁵ hours is ≥80MPa).

Fatigue resistance performance:

After quenching and tempering treatment, the fatigue limit reaches 40% of the tensile strength (e.g., 316-hour fatigue life ≥10⁷ cycles).

Corrosion resistance:

In an environment containing Cl⁻, the pitting corrosion equivalent (PREN) of duplex steel 2205 is ≥32, which is superior to that of 316L (PREN≈25).

Welding reliability:

316L pipes are welded with ER316L welding wire, and solution treatment is carried out after welding. The joint strength is ≥ 95% of the base material.

Application field

Electricity: Main steam pipeline of supercritical/ultra-supercritical power station (pressure 25-30 mpa, temperature 566-620℃).

Chemical industry: High-pressure pipe for ammonia synthesis plant (transporting NH₃, H₂ and other media, pressure 15-32 mpa).

Petroleum extraction: Oil well casing, fracturing manifold (high-pressure oil and gas extraction, pressure ≥70MPa).

Nuclear power: Main circuit pipeline of the nuclear island (coolant transportation, pressure 15.5MPa, temperature 310℃).

Aerospace: Hydraulic system pipelines (such as aircraft landing gear, pressure 28MPa), rocket engine fuel pipelines.

Marine engineering: Offshore platform water injection system (high-pressure water flooding for oil, pressure 40-60 mpa).

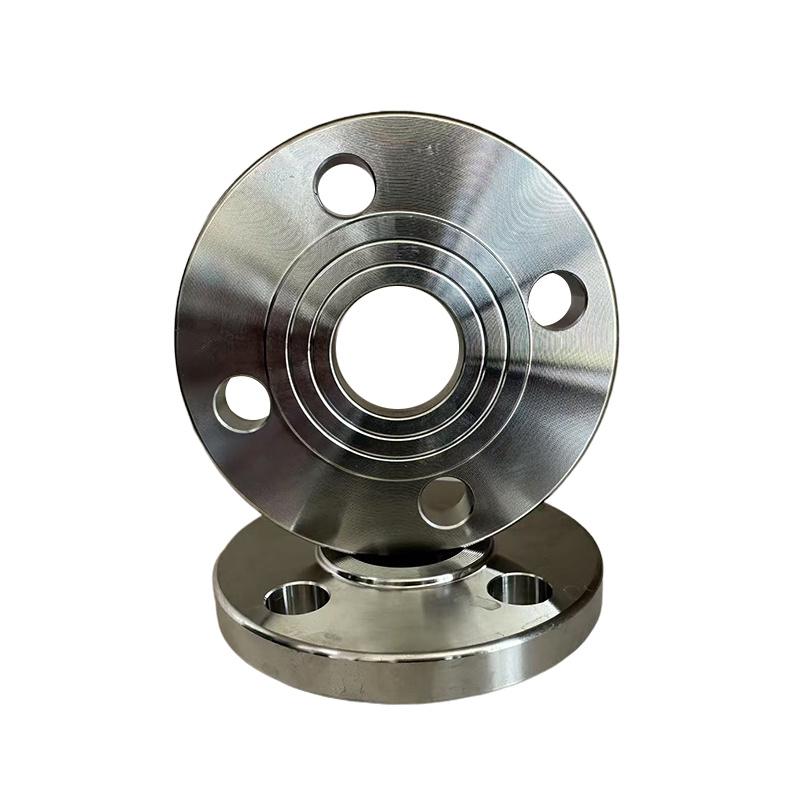

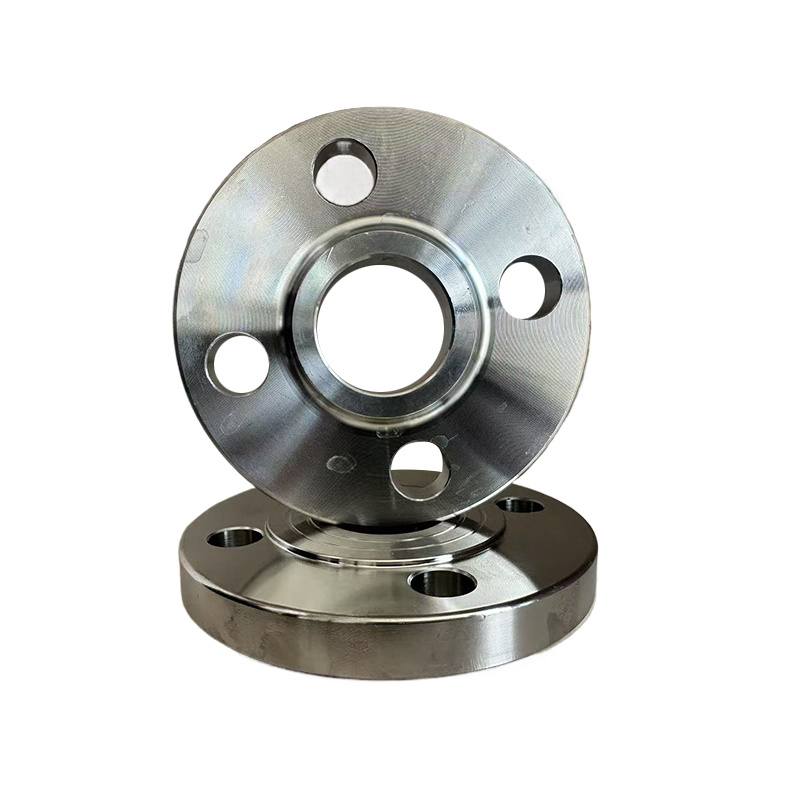

Factory display

Logistics delivery

FAQ

What is your payment service?

Accepted delivery terms: FOB, CFR, CIF, EXW;

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C;

What can we buy from you?

Our company provides high-pressure seamless steel pipes, stainless steel seamless pipes, oil pipes, boiler pipes, spiral welded pipes, elbows, flanges, elbows, pipe caps, high-pressure pipe fittings, thermal insulation, anti-corrosion, plastic-coated pipe fittings and other products.

How to ensure quality?

There are always pre-production samples before mass production; there is always a final inspection before shipment;

Do you accept OEM/ODM service?

Yes, we can produce products according to your requirements.

Get Quote

*We will contact you within one working day. Please pay attention to your email.

Related Products